Circular Product Development: Lifecycle Thinking Beyond Sustainability

What is Circular Product Development?

Circular product development is a strategy for designing products that actively enable reuse, modular repair, remanufacturing, and recycling, all within a closed-loop system. This forward-looking approach views products not as disposable commodities, but as catalysts for long-term positive impact.

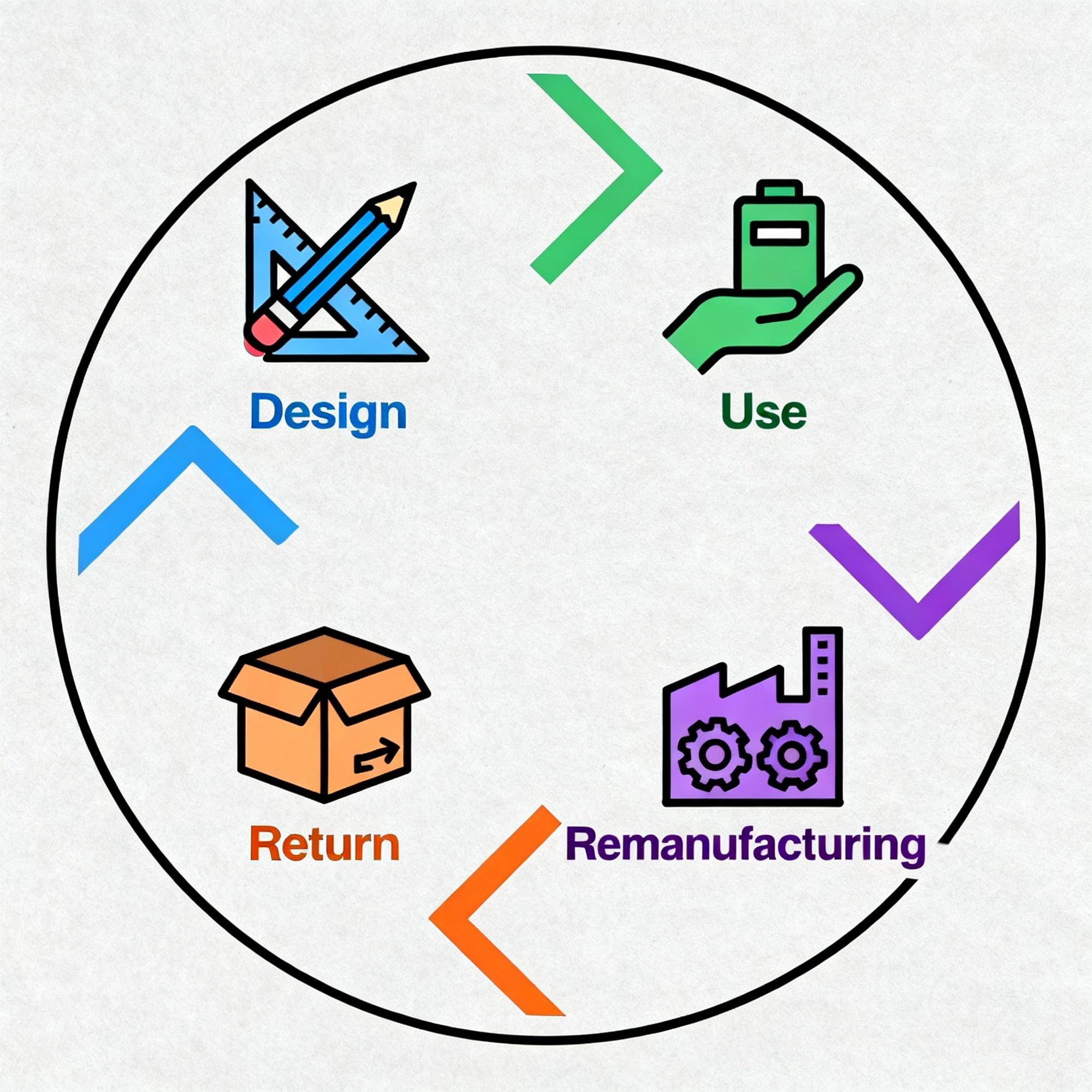

Visualizing the Circular Lifecycle

The circular lifecycle image shows four key stages, each vital to circularity:

Design: Products are created for durability, easy repair, and eventual disassembly, maximizing usable life and future material value.

Use: Items are used to their greatest potential, with maintenance and upgrades encouraged to extend functionality.

Return: After primary use, products or components are returned through organized take-back or collection systems, preventing waste.

Remanufacturing: Returned materials are remanufactured, refurbished, or recycled, re-entering production to begin the cycle again.

Expanding the Stages: Lifecycle Points

Each lifecycle phase involves targeted actions:

Raw Material Sourcing: Selecting recycled or renewable materials at the outset reduces environmental impact and dependency on finite resources.

Manufacturing: Processes are optimized for minimal waste, energy efficiency, and potential for disassembly, supporting easier recovery and reuse.

Distribution and Logistics: Thoughtful packaging, shared logistics, and reverse logistics systems lower carbon footprints and facilitate returns.

Product Use: Digital monitoring and predictive maintenance increase longevity, while modular design enables upgrades without complete replacement.

Collection and Reverse Logistics: At end-of-use, efficient collection routes bring products back for sorting, refurbishment, or recycling—integral for closing the loop.

Refurbishment and Remanufacturing: Items are cleaned, restored, or remanufactured—extracting new value and reducing reliance on virgin materials.

Recycling: Materials and components that can no longer be reused are broken down and returned to the start of the value chain, ensuring nothing is wasted.

Business and Environmental Benefits

Circular product development delivers value far beyond environmental stewardship:

Cost Savings: Lowered raw material costs and waste disposal fees through reuse and recycling.

New Revenue Streams: Offering maintenance, refurbishment, and take-back services unlocks secondary markets.

Brand Reputation: Compliance with repairability and durability regulations boosts trust and brand equity.

Reduced Carbon Footprint: Circularity at scale dramatically reduces emissions by minimizing new resource extraction and energy use.

Technology and Innovation Driving Circularity

Digital twins and simulation tools, as referenced in leading industry applications, now allow designers to test disassembly, repair, and material options before products are launched. Real-time data and predictive analytics deliver ongoing insights for optimizing product performance and circularity at every stage.

Closing the Loop in Organizations

Organizations like Schneider Electric exemplify end-to-end circularity, integrating eco-design, reverse logistics, and refurbishment into every business unit. Collaborative supply chain strategies, digital asset tracking, and condition-based maintenance extend life, minimize waste, and uncover new business value.

Lifecycle Thinking: Practical Steps

Prioritize sustainable, circular materials from the outset

Design every product for repair, reassembly, and disassembly

Implement smart logistics and return systems

Create incentives for customers to return used products

Embrace digital tools for monitoring, traceability, and life extension

Conclusion

Circular product development represents a fundamental shift from linear “take-make-dispose” to a regenerative system explicitly designed to benefit people, planet, and profits. When lifecycle thinking is embedded into each stage, waste is eliminated as a concept, unlocking new sources of value and resilience for the future.